Technical Innovation

Comprehensive Guide to PTFE Mandrels

Published by VasPilot Healthcare

Precision Components for Medical Device Manufacturing

What Is a PTFE Mandrel?

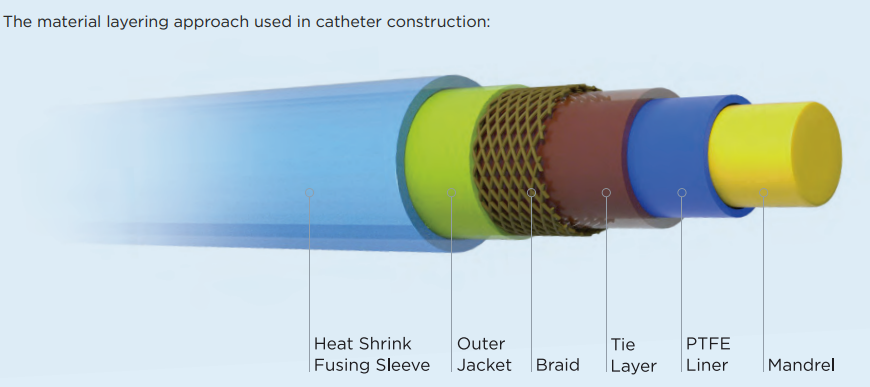

A PTFE Mandrel is a solid core, typically made from polytetrafluoroethylene (PTFE), used during catheter and medical tubing manufacturing to define and stabilize the inner lumen. Mandrels are inserted into liners or tubing during extrusion, reflow, bonding, or lamination processes, and later removed to leave a smooth, dimensionally accurate internal channel.

PTFE is widely selected for mandrel applications due to its exceptional lubricity, chemical inertness, thermal stability, and medical‑grade biocompatibility.

Key Characteristics of PTFE Mandrels

1. Ultra‑Low Friction & Easy Release

PTFE has one of the lowest coefficients of friction among solid materials, allowing mandrels to be removed smoothly after processing without damaging delicate catheter structures.

2. Thermal & Chemical Resistance

PTFE mandrels maintain dimensional stability during high‑temperature reflow, heat‑bonding, and lamination processes, and are resistant to solvents, adhesives, and cleaning agents commonly used in medical manufacturing.

3. Biocompatibility

Medical‑grade PTFE materials are biocompatible, making them suitable for producing components used in cardiovascular and neurovascular interventions.

4. Tight Dimensional Tolerances

High‑quality PTFE mandrels can be manufactured with extremely tight tolerances, supporting consistent inner diameter (ID) control and repeatable device performance.

Glass‑Filled PTFE Mandrels

Glass‑filled PTFE mandrels combine the lubricity of PTFE with improved stiffness and dimensional precision. This enhanced rigidity is particularly valuable for microcatheter and multilumen designs.

Key advantages include:

Improved dimensional consistency

Enhanced compressive strength

Reduced mandrel deformation during processing

Quick‑release designs that stretch or compress for easy removal

Faster production cycles and improved yield

These mandrels are increasingly used in neurovascular and advanced catheter manufacturing where precision and efficiency are critical.

Applications of PTFE Mandrels

Catheter Manufacturing

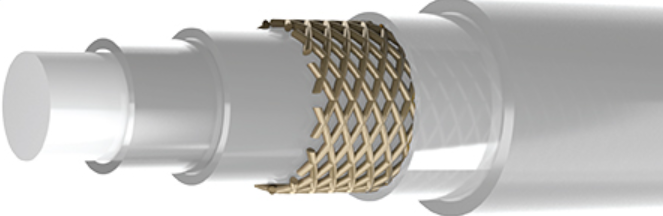

PTFE mandrels are used during extrusion, braiding, reflow, and jacket bonding to maintain smooth and accurate internal lumens.

Balloon Catheter Production

Mandrels support balloon forming and bonding processes, ensuring consistent inflation geometry and internal surface quality.

Microcatheters

In neurovascular microcatheters, PTFE and glass‑filled PTFE mandrels support ultra‑small diameters while enabling gentle extraction from finished assemblies.

Multilumen Devices

Complex multilumen catheter designs require multiple mandrels to define each channel during lamination and consolidation processes.

Role in Advanced Microcatheter Manufacturing

Modern microcatheter production often combines PTFE mandrels with advanced liner and tie‑layer technologies. Tie layers improve adhesion between PTFE liners and outer catheter jackets, increasing bonding strength, reducing delamination risk, and improving manufacturing yield — all without increasing device profile.

Together, mandrels, liners, and bonding layers form a complete PTFE‑based ecosystem supporting high‑performance catheter design.

Technical Comparison: PTFE Mandrel Types

| Feature | Standard PTFE Mandrel | Glass-Filled PTFE Mandrel |

|---|---|---|

| Lubricity | Excellent | Excellent |

| Dimensional Stability | Good | Excellent |

| Stiffness | Moderate | High |

| Ease of Removal | Excellent | Excellent (Quick-Release) |

| Deformation Risk | Low | Very Low |

| Typical Applications | General catheters | Microcatheters, multilumen designs |

Choosing the Right PTFE Mandrel

When selecting a PTFE mandrel, manufacturers should consider:

Required inner diameter and tolerance

Mandrel stiffness and straightness

Thermal processing conditions

Ease of removal and reusability

Compatibility with catheter materials

Working with an experienced supplier ensures optimal mandrel performance across development and production stages.

Why VasPilot Healthcare?

VasPilot Healthcare supplies precision PTFE mandrels and fluoropolymer solutions tailored for catheter and interventional device manufacturing. Our focus on dimensional accuracy, material quality, and application support helps customers achieve reliable, scalable production outcomes.

Contact VasPilot Healthcare

To learn more about custom PTFE mandrels, liners, and fluoropolymer components for medical devices.

RELATED NEWS

- Microcathter - Construction and Components 2024-11-29

- VasPilot - Applications - PET HEAT SHRINK TUBE 2024-12-01

CATEGORIES

LATEST NEWS

CONTACT US

Contact: Admin

Phone: +86 1989 6688 185

E-mail: info@vaspilot.com

Whatsapp:8619896688185

Add: Shanghai, China